Why you need to watch out for water hammer

How to avoid expensive damages and prolong the life of your equipment

It’s the phenomenon that no engineer wants to happen. Unpredictable, worryingly powerful, and with the potential to cause serious harm both to people and infrastructure, water hammer is high on the list of hazards no one wants to experience.

Caused by a sudden pressure change in pipelines or other equipment, the stress of this pressure shock can travel at the speed of sound, with devastating results. The first sign of water hammer is often an ominous knocking sound, sometimes quite forceful in pitch.

There are two main types of water hammer:

- Hydraulic water hammer: found in installations with cold liquids

- Thermal water hammer: in steam and condensate systems and hot water installations

What causes hydraulic water hammer?

Imagine liquid flowing through a pipeline which is stopped by a rapidly closing valve. The liquid upstream from the valve suddenly has nowhere to go, creating a pressure shock. Since liquids are almost incompressible, this reverberates in all directions.

Just below the shut-off valve, the liquid’s flow doesn’t stop immediately, which creates a vacuum. This draws the liquid back to hit the valve, causing a pressure wave. This rebounds, back-and-forth, gradually losing its strength.

What causes thermal water hammer?

Here water hammer is caused by steam, or flash steam, that mixes with condensate at a lower temperature. The result is that the steam bubbles collapse abruptly, causing a vacuum. The surrounding condensate rapidly fills this space causing an implosion, with the liquid particles colliding at high velocity resulting in high-pressure peaks.

4 key reasons for thermal water hammer

- Faulty installation of valves and equipment and poorly designed pipework

- Careless operation of valves (especially during the start-up process)

- The use of unsuitable or wrongly-sized equipment

- Faults within the equipment

Exactly how forceful the water hammer will depend on the intensity or amount of mixing between steam or flash steam and condensate at a lower temperature than saturation temperature.

For example, take an inadequately drained steam or condensate line where steam flows at a higher velocity than the condensate. If there is the presence of cooling condensate in a steam distribution main and it accumulates to form a slug of condensate in the pipe, that slug will attain the velocity of the steam travelling in the pipe. When the slug of condensate hits a component (such as a valve) or change in direction in the pipe (from horizontal to vertical), its kinetic energy will impart shocks to the system resulting in water hammer. In another scenario, if live or flash steam enters a flooded condensate line, the steam will quickly cool and implode create a rapid vacuum causing a shock wave that causes waterhammer.

Guarding against water hammer

When it comes to avoiding hydraulic water hammer, it is possible to calculate the potential effects and where they might occur. The potential pressure shocks can then be avoided, or at least dampened, by the correct sizing of valves and pipelines and the use of specific equipment, like the GESTRA BB-type check valve with dampers.

For thermal water hammer, there is no simple way to gauge its possible severity. It should be considered at the design and installation stage of the plant, and in its day-to-day operation. If a plant is properly designed, installed, and competently operated, water hammer shouldn’t be a problem.

If this isn’t possible, then measures should be taken to use equipment to provide effective dampening of any potential instances of water hammer.

Two practical ways to avoid water hammer

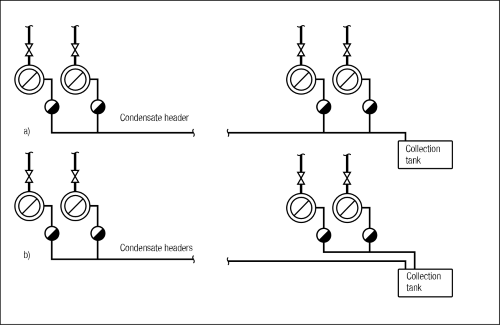

Taking condensate drainage lines as our case study, figure a) shows what happens when heat exchangers some distance apart share the same condensate lines. Because the condensate from the first set has cooled by the time it reaches the next, the flash steam from the second set of exchangers will rapidly implode when it mixes with the subcooled condensate, causing water hammer.

The solution, shown in figure b), is to have separate condensate headers for each set of exchangers. This avoids the mixing of different temperatures and the potential for water hammer. This would also be a best practice where condensate from exchangers with different load conditions is being returned to the same condensate tank.

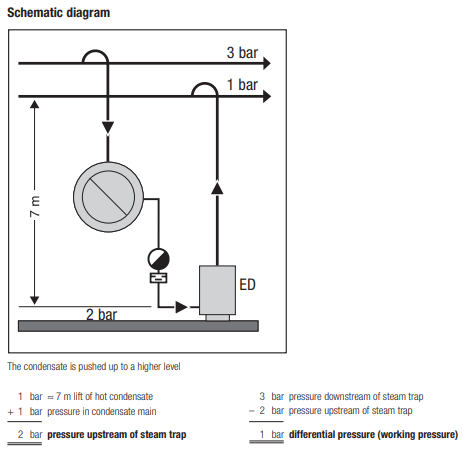

In this second example, water hammer will occur due to the condensate being lifted to a higher level. The solution in such cases is to reduce the impact of water hammer by installing a GESTRA ED-type damping pot. This device works to mitigate water hammer, both at start-up and during normal operation, by cushioning the effect of the water hammer.

Worried about water hammer in your system?

With so many variations in steam and condensate systems, there’s rarely just one solution to avoiding water hammer. If you have experienced unusual sounds, especially when starting up a system, then it will pay to consult an expert.

For over 120 years GESTRA has led the field in diagnosing and improving steam systems, helping prevent water hammer by applying best-in-class knowledge to each unique case around the world.

Our engineers are at your service, whatever the size of your problem, and wherever you may operate