GESTRA 360

Complete steam trap solutions to optimise your process

GESTRA 360 can help you

Improve system reliability

Increase productivity and efficiency

Be more sustainable

Steam trap management and digital optimisation

As a manufacturer, steam is the best way to get the right level of heat to where you need it in your process. But could your steam system be working even harder for you? If you’re looking to improve your productivity while reducing energy waste and emissions, GESTRA 360 can help.

What can GESTRA 360 do for you?

GESTRA 360 can help you:

1. Get the most out of your steam traps

Have you been struggling with excessive downtime in your process recently?

If you’re looking to improve uptime onsite, then better steam trap management could be the answer.

A dedicated steam trap survey is a good place to start. A survey will provide an overview of how effective your steam traps are at getting energy to your process.

Effective steam trap management can:

- Detect problem steam traps quickly so they can be repaired or replaced.

- Guide data-driven benchmarking and process performance improvements.

- Help meet your sustainability targets.

- Reduce costs and improve safety onsite.

Regular steam trap testing couldn’t be easier with our world-renowned GESTRA TRAPtest VKP. This testing tool quickly and accurately analyses each steam trap using ultrasonic vibration and temperature checking.

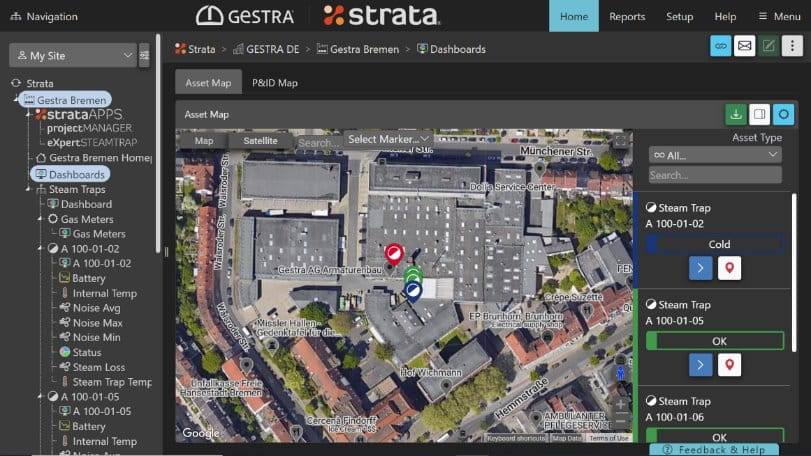

Meanwhile, GESTRA’s cloud-based diagnostic portal can help visualise your system performance. You can track the CO2 emissions, steam losses and associated costs of up to 20,000 steam traps, regardless of who manufactured them. Based on your steam trap performance data, you’ll be offered guidance on how to prioritise maintenance to achieve an optimal steam system.

Whatever the size of your system, a Steam Trap Survey can help optmise your system to its full potential.

Case study: BASF

Read more about how BASF benefits from regular steam trap testing

2. Get the quality parts you need, when you need them

If you’re finding it hard to trust the quality of your steam system supplier, GESTRA can help resolve your quality concerns.

GESTRA’s proud engineering and manufacturing history makes us the perfect steam system service and installation partner. We can help make your process more reliable and strengthen your steam system performance. You can trust that each product and solution is manufactured to the highest standards and installed properly, every time.

3. Optimise your entire steam system

Not sure how you can achieve your energy reduction targets?

Auditing your whole steam system can help unlock potential energy savings and show opportunities for improvement or standardisation in your production.

Our experts can help you to control your assets more effectively with a comprehensive Steam and Condensate System Audit

4. Get connected

If you’re struggling to keep on top of regular steam trap surveys, give your maintenance team a break and track them digitally.

Remote steam trap monitoring is more powerful than periodic manual checks because you can get performance insights quickly and calculate any energy waste, emissions and cost associated with problem steam traps.

Our ecoBolt sensors and intuitive diagnostics dashboard give you the power to make your connected steam system more efficient and sustainable.

Our steam experts will use their unrivalled steam knowledge to turn powerful data insight from your steam traps into real world improvements in your plant.

We’re proud to be at the forefront of our industry, shaping it’s future so that you can continue to benefit from steam on your path to be more sustainable. Our pioneering solutions, quality engineering and reliable expertise has been recognised by EcoVadis, the world’s largest and most trusted provider of business sustainability ratings.Read more about our rating

Start benefiting from GESTRA 360

You can rely on GESTRA 360 to help improve your system reliability, save energy, reduce emissions and lower unplanned downtime.

Whether it’s to discuss your next survey or the benefits of digital steam trap monitoring, if you need advice that you can trust, talk directly to the people who’ve been building world-class steam systems for over 120 years.

Related Content

Steam system audits

Identify hidden opportunities to save energy and improve reliability and productivity in your system.

Steam trap surveys

Improve performance by identifying failing steam traps in your steam system.

ecoBolt Wireless Steam Trap Monitoring

Unlock extra layers of your site potential related to Sustainability, Energy and Financial gains. Enhance your steam trap testing regime by adding GESTRAs latest steam trap-specific sensing technology coupled with an intuitive algorithm-enabled digital dashboard.